Omniasystem advantages

Two components to encompass the limitless

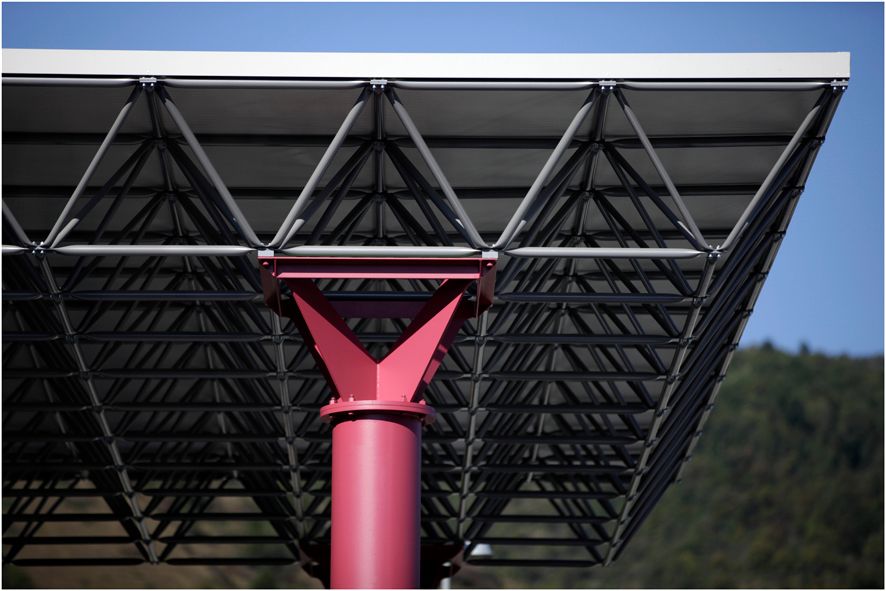

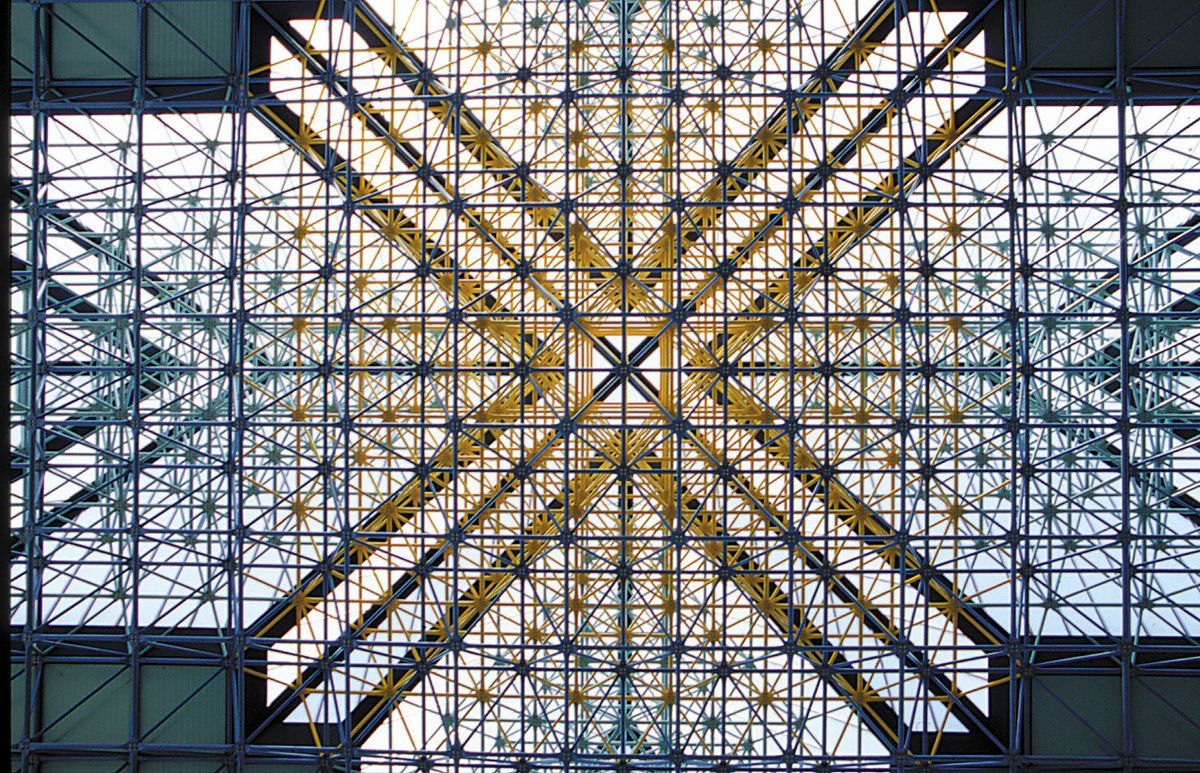

Utilizing a patented system for element connection, exclusively through bolting, structural expansions become inconsequential as each grid or diagonal expansion is absorbed by the junction node. The spatial grid structures provided by Omnia Structures enable the creation of robust steel roofs that are lightweight and offer extensive compositional flexibility. They are convenient to transport and assemble.

All grid components are crafted from S235JR steel, hot-dip galvanized both internally and externally. The bolts, branded Omnia, are graded 8.8 and coated with 8 microns of white zinc.

Considering the extensive expertise in thefield of large-scale roofing for industrial warehouse.

Explore our projects

Discover how our Omniasystem has been featured across a wide range of large-scale projects

Assembly in three simple steps

The Omniasystem focuses on modularity and streamlining assembly processes

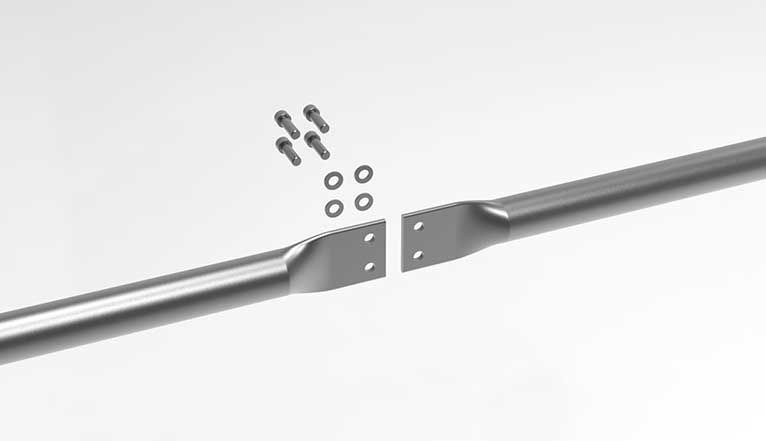

Step 1

Installing screws and grid steel tubes

Place the M12 screw, washers, and the initial set of grid steel tubes.

The precision and accuracy in Omniasystem’s production ensure seamless fits and connections.

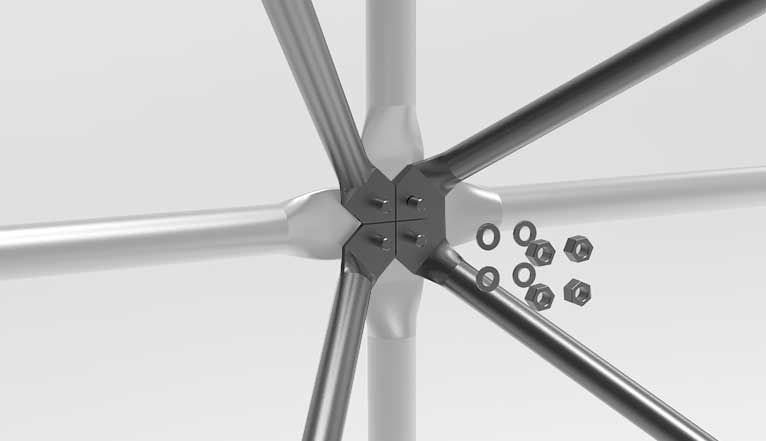

Step 2

Placing grid steel tubes

Position the M12 screws, washers and the second set of grid steel tubes

Once the second set of grid steel tubes is in position, the module stabilizes, ensuring a secure connection between the components.

Step 3

Placing and securing

Position the diagonals and secure them with washers

With this step completed, the module is fully assembled and ready to replicate for the final structure

The module tailored to your requirements

Omnia Structures spatial grid structure enable the construction of sturdy and durable steel roofs that are also lightweight and offer considerable compositional flexibility. They are convenient to transport and assemble.

Utilizing a patented system for element connection, exclusively through bolting, structural expansions become inconsequential as each grid or diagonal expansion is absorbed by the junction node.

Download Catalogues

.png)