Omniablok benefits

MINIMUM FASTENING MAXIMUM BENEFIT

The system for roof and impossible installations

Discover all the advantages of our structure for photovoltaic solar panels.

No ballast weight

Being a modular reticular linked structure

Full Assembly Kit

Elements are interconnected solely through bolt connections

No drilling

The mounting of the structure requires few fasteners in the roof

Design/Estimates

Omnia team is at your disposal for technical support and quotation

Shield against atmospheric agents

Resists against atmospheric agents.

Tailored To Fit

The System is meticulously designed to match the roof and installation location specifications

Walkable

The photovoltaic panel rests entirely on the perimeter.

Thermal Expansions

The photovoltaic panel is locked at the four corners

Tilting panels

with a 0° to 25° tilt according to the customer’s request

Certified

Upon request, the wind resistance certification is provided

Lightweighted

The structure’s weight is minimized due to its complete connectivity

Quick laying

Error risk-free quick-laying

20 years warranty

Longlasting granted

Patented

In Italy and abroad

Shield against atmospheric agents

Resists against atmospheric agents.

Certified

Upon request

Assembly in three simple steps

The design of Omniablok aims to streamline installation times

Step 1

Module Placement

Position the male Omniablok casting onto the roof surface, then place the grid element steel tube

The Omniablok casting has been engineered for easy installation, allowing swift and precise positioning of components right from the initial setup

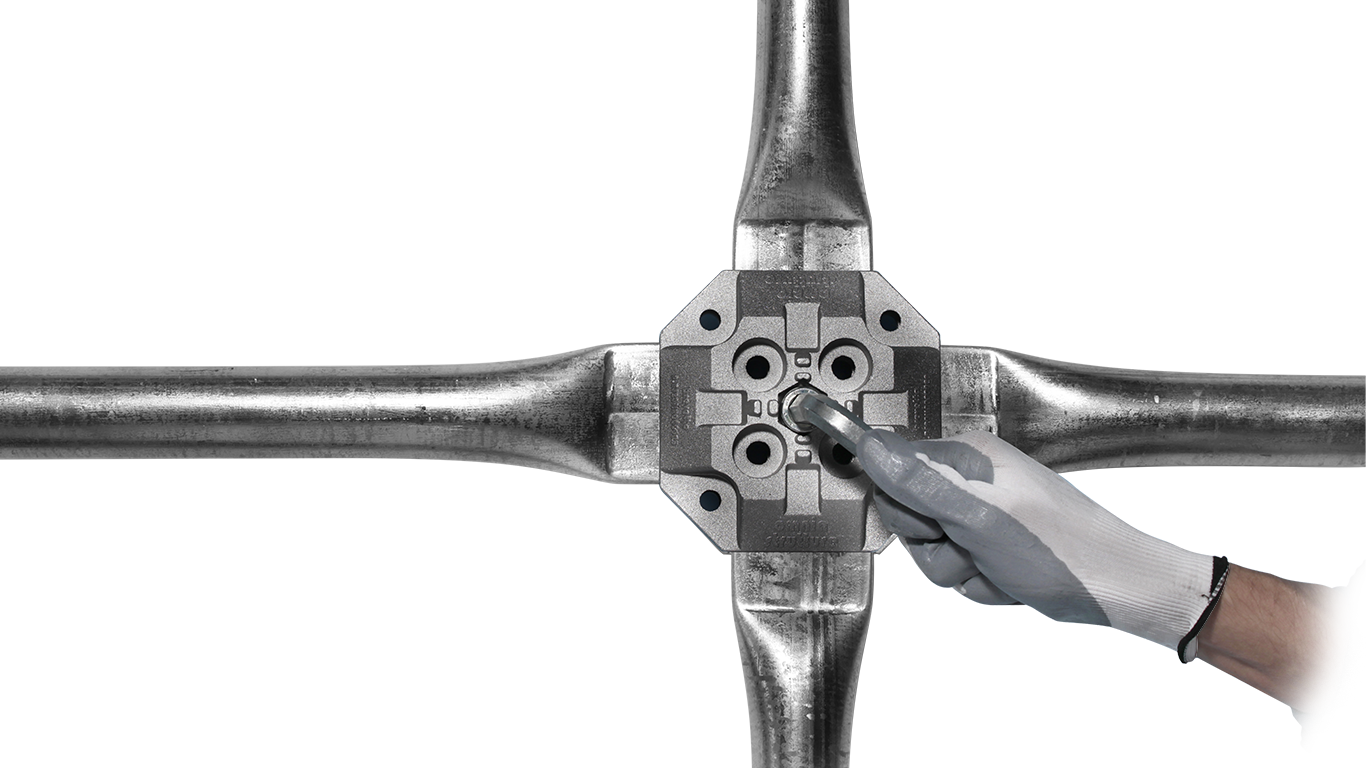

Step 2

Fastening the module

Position the female Omniablok casting in alignment with the male casting, then secure it using the central M16 screw.

The locking mechanism is facilitated by a single central screw. The design of the casting and grid ensures a stable and durable node, capable of withstanding stress.

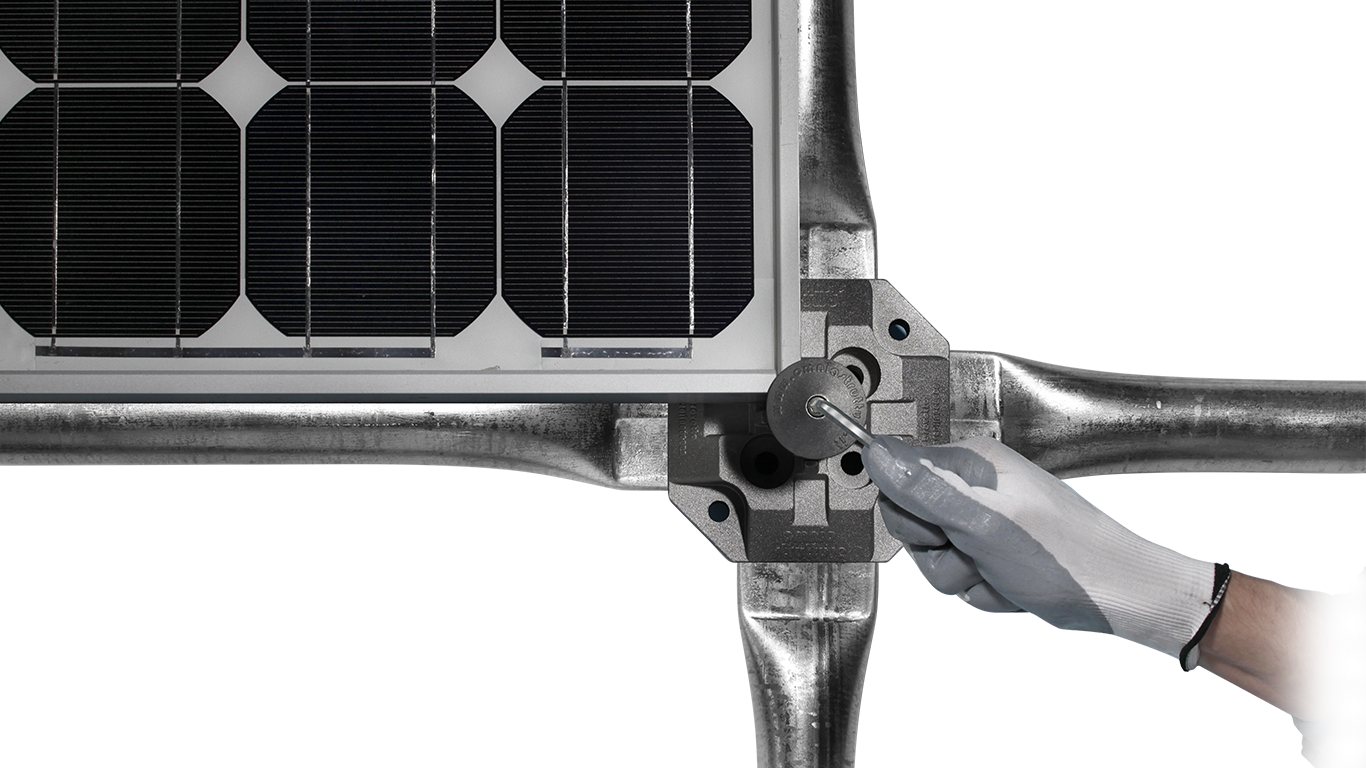

Step 3

Panel Placement

Position on the panel on the grid support, then secure it using the panel stopper washer.

The groove designed in the casting and the panel stopper washer ensure the panel stays in place facilitating both the installation and potential maintenance tasks.

A solution applicable to all construction materials

The modularity combined with the customized nature of our product makes it a versatile module suitable for various shapes and surfaces.

Frequent questions

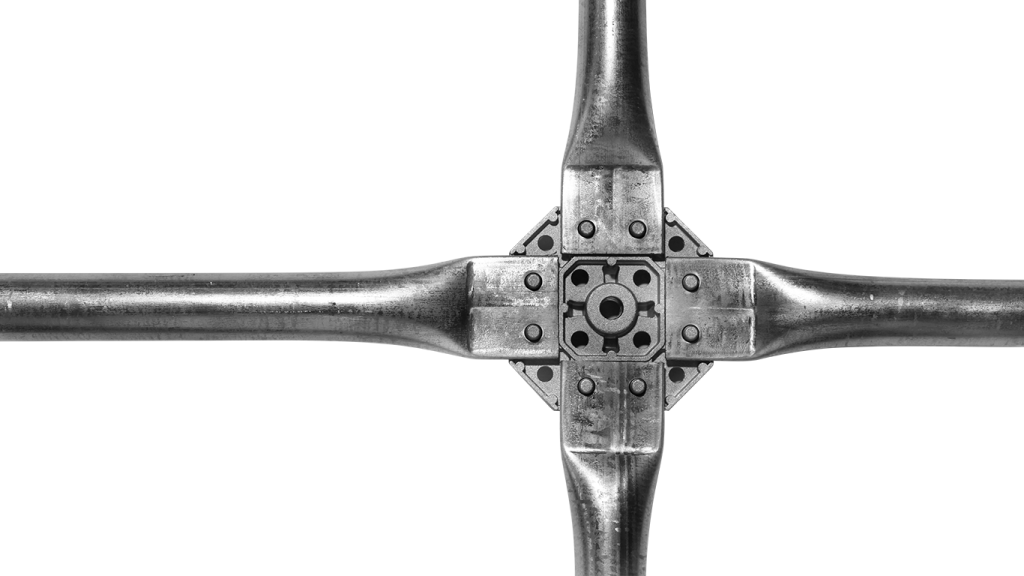

Omniablok is a structural support system for the photovoltaic panels, developed and introduced to the market by Omnia Spatial Structures SRL since 2010. It derives its name from the Omniablok aluminium casting, crafted from EN AB 46100 alloy, enabling the connection of grid elements forming the photovoltaic frame.

The Omniablok structure comprises hot-dip galvanized s235 steel tubes, lightweight aluminium alloy castings, and the bolts are fabricated from A2 stainless steel, all branded “OMNIA”.

The number of fasteners depends on the layout, the type of the roof, and the installation area;

each structure is customized based on its specific characteristics, and the fastening points vary accordingly. Our technicians create a design indicating the fastening points, typically positions along the perimeter of the roof, aiming to avoid fixings inside the roof slope.

One of the advantages of the Omniablok system is the ability to install with minimal drilling compared to the traditional standard structures.

No, each Omniablok structure is tailor-made according to the dimensions of the photovoltaic panel to be installed.

No, Omniablok structures are straightforward and fast to assemble.

Installers can assemble Omniablok instead of standard systems without needing to attend training courses.

The Omniablok structure weighs around 9.8 kg/m2 for a flat roof and approximately 6.5 kg/m2 for a sloped roof. The weigh can vary depending on the size of the photovoltaic panel.

No, our systems are tailored for roofs and are developed from our extensive expertise in roofing solutions

Are additonal clamps required for installation? No, the Omniablok structure comes complete with bolts and all necessary components for panel attachment

Certainly upon request, we can supply a snow guard for the end section of the structure, or a snow guard to be installed among the photovoltaic panels

You can request a quote by emailing info@omniastrutture.it

and attaching a layout showing module arrangement, technical data sheet of photovoltaic panels, shipping address, and any available photos of the roof